Modular House Assembly Timeline: From Factory to Occupancy

Factory Manufacturing Phase: Precision and Parallel Workflow

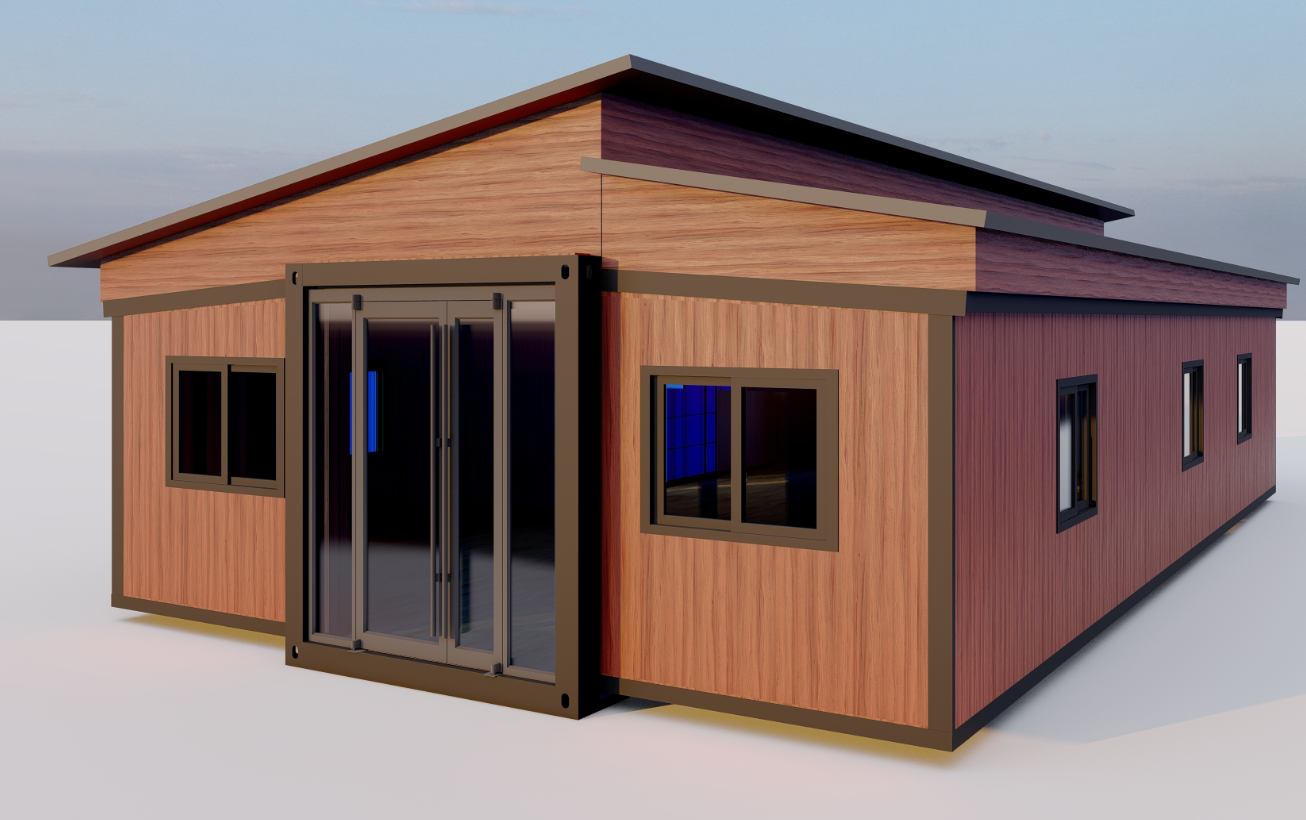

The construction process for modular homes starts inside climate controlled factory environments where precise engineering meets efficient workflow systems that really speed things up. While traditional builders wait out bad weather, these factories keep right on going because walls, floors, and entire roof sections get built all at once along assembly lines. Quality control isn't an afterthought here either. Every module gets checked thoroughly at different points in the line to make sure everything meets building code standards and local requirements before they ever leave the plant. Most of this factory work wraps up in around six to eight weeks, which cuts down building time by about forty percent compared to regular stick frame construction methods. And while all this is happening inside, crews outside are already getting ready for installation too. Land clearing and pouring foundations can happen at the same time as manufacturing, so the whole project timeline gets compressed significantly.

On-Site Delivery, Crane Installation, and Structural Integration

When everything is ready at the factory and the building site is prepared, the modules get moved over to their destination. Big specialized cranes lift each unit into place on top of the foundation and then bolt them together to form one solid structure. Putting all these pieces together involves sealing the gaps between modules, installing shear walls for stability, and making sure the roof fits securely. Most of this work gets done pretty quickly, usually taking anywhere from one day up to four days total. Getting those cranes in position right from the start saves a lot of headaches later on, while attaching the structural components doesn't require much hands-on work by local crews. What makes modular construction so appealing? It turns what would normally take several months of step-by-step building into something that can be assembled in just a few days when everything goes smoothly.

Final Inspections, Utility Hookups, and Move-In Readiness

Once the structure is put together, workers start hooking up the essential services between different parts of the building and connecting them to city infrastructure. This part tends to be where projects run into trouble with schedules getting backed up. The interior stuff gets finished off around the same time too - things like patching drywall seams, installing baseboards, and laying down floors. Then comes the big check from local inspectors who want to see if everything meets building codes before people can actually move in. Even though most parts come from factories already made to standard specs, this whole process still takes anywhere from four to six weeks because different trades need to coordinate their work and wait for those official inspections. Getting ahead on utility connections makes all the difference when trying to get ready for residents to show up according to plan.

Key Factors That Accelerate or Delay Modular House Assembly

Design Standardization vs. Customization Trade-Offs

When it comes to building projects, standardized modular designs really speed things up. The Modular Building Institute reports these methods can cut factory production times by anywhere between 30% to 50%. Manufacturers spend extra time getting those floor plans just right and specifying materials that work well together on the assembly line. This attention to detail means fewer last minute changes and less waiting around for materials to arrive. But when clients want something different, like windows placed where they don't normally go or fancy finishes that aren't standard, everything gets complicated. These custom requests throw off the whole workflow sequence. Every time there's a design change, workers end up spending extra days fixing problems and dealing with components that don't fit properly at the construction site. Take complex roof junctions for example. They need special checks and balances throughout manufacturing, which naturally takes longer than straightforward installations.

Site Preparation, Permitting, and Utility Coordination

Doing site work at the same time helps avoid delays. The foundation needs to be poured while the trenches for utilities are dug, all timed to match when the modules arrive on site. Some places have special permits for modular construction, as seen in California and Washington for instance. These can get approved within four weeks, which is about 60 percent quicker compared to normal processes. But things go wrong too often. Soil testing takes longer than expected, or the power and water connections aren't ready when needed, so cranes just sit idle. City modular builds typically face delays between three to eight weeks because of hidden utility lines below ground. Getting ahead of these issues means talking regularly with local inspectors before problems happen, something many contractors learn through experience rather than reading manuals.

Modular House vs. Traditional Construction: Quantifying Time Savings

Building modular houses gets completed way faster than regular construction because multiple parts happen at once instead of one after another. Traditional homes take forever since they build everything step by step, often getting stuck waiting for good weather, enough workers, or finalizing plans. Meanwhile, modular components get made in factories while the foundation is being laid on site. Industry folks at NAHB and MBI say this overlap cuts down overall time by about 30 to 50 percent. Why does this work so well? Factories allow for precise manufacturing without weather delays, and putting everything together happens much quicker thanks to cranes doing most of the heavy lifting. Take foundation work and interior finishes for instance these days they happen side by side rather than waiting for each other to finish first. Custom features might slow things down a bit, but standard designs mean people can move in within weeks not months which makes all the difference when someone needs a place to live fast.

Real-World Case Examples: Modular House Assembly in Action

Single-Family Residential Project: 65-Day Total Timeline

A family in suburban Oregon recently moved into their new home just 65 days after breaking ground on the project. The builders prefabricated all the main modules at their factory over 28 days while workers cleared and graded the land at the same time. Getting everything assembled on site took barely five days thanks to cranes lifting the pieces into place. Then came the messy part - hooking up utilities and finishing interiors inside those modules which took another month plus. This approach sidestepped those frustrating rain delays that plague normal construction schedules, so the family actually got keys two months earlier than neighbors building similar houses conventionally. Modular construction still faces some skepticism about quality concerns, but this case shows standardized factory-built components can deliver homes much quicker when planned right from start to finish.

Multi-Unit Affordable Housing: 4-Month Turnkey Delivery

A new affordable housing complex in downtown Seattle managed to complete 32 residential units within four months thanks to modular building techniques. The actual factory work took about ten weeks total before shipping started, with prefabricated sections arriving at the site in carefully planned waves. Workers on location managed to put together between four and six homes each day using those big cranes everyone sees around construction zones. What's really impressive is that residents were able to move in five whole months earlier compared to traditional stick built projects nearby, all while saving nearly 18 percent on overall expenses. These kinds of timelines show why more cities are turning to factory made housing solutions when dealing with their growing homeless populations and lack of available shelter options.

Frequently Asked Questions

What are the advantages of modular houses over traditional construction?

Modular houses can be assembled quickly, reducing construction timelines by up to 50% compared to traditional methods. They offer better quality control and less susceptibility to weather delays.

How do modular houses ensure quality and compliance with building codes?

Modules are manufactured in a factory setting with strict quality checks. These checks ensure each module complies with building codes and standards before installation.

What can cause delays in modular house assembly?

Delays can occur due to design customization, site preparation issues, permitting delays, and utility coordination problems.

Can modular construction be used for both single-family homes and multi-unit buildings?

Yes, modular construction is versatile and can be applied to both single-family homes and larger multi-unit buildings, including affordable housing projects.

How does modular construction impact project costs?

Modular construction can reduce overall project costs by optimizing material use, minimizing labor hours, reducing weather-related holdups, and expediting project completion.

Table of Contents

- Modular House Assembly Timeline: From Factory to Occupancy

- Key Factors That Accelerate or Delay Modular House Assembly

- Modular House vs. Traditional Construction: Quantifying Time Savings

- Real-World Case Examples: Modular House Assembly in Action

-

Frequently Asked Questions

- What are the advantages of modular houses over traditional construction?

- How do modular houses ensure quality and compliance with building codes?

- What can cause delays in modular house assembly?

- Can modular construction be used for both single-family homes and multi-unit buildings?

- How does modular construction impact project costs?